Repair quality measurements (RQM) are essential tools in auto restoration, enabling professionals to accurately assess and guarantee vehicle repairs. Advanced techniques like laser measurement and digital imaging ensure panel alignment, paint quality, and structural integrity meet strict standards. By implementing RQM, collision repair shops enhance customer satisfaction, vehicle safety, and their market reputation. Clear criteria, KPIs, staff training, and open communication are vital for consistent, high-quality body services.

In the meticulous art of auto restoration, precision is key. Enter repair quality measurements—essential tools for ensuring every fix meets the highest standards. This article delves into the fundamental concepts of repair quality measurements, highlighting their pivotal role in preserving automotive history and craftsmanship. We explore why these measurements are crucial, offer best practices for implementation, and provide insights on evaluating restoration work accurately. By understanding and adopting these principles, restorers can elevate their craft to new heights.

- Understanding Repair Quality Measurements: The Basics

- Why Repair Quality Measurements are Crucial in Auto Restoration

- Implementing and Evaluating Repair Quality Measurements: Best Practices

Understanding Repair Quality Measurements: The Basics

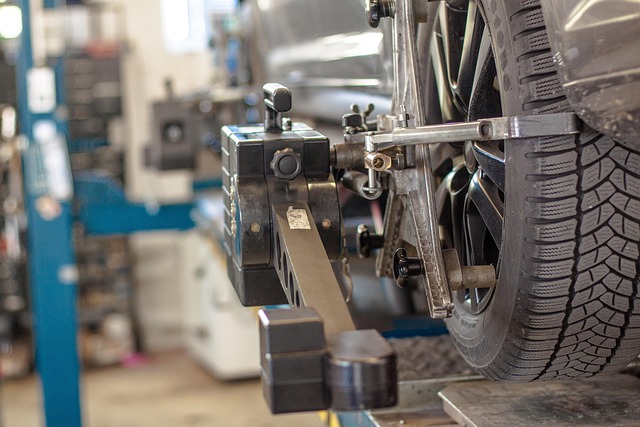

Repair quality measurements are essential tools for auto restoration professionals. They provide a standardized way to assess and evaluate the work done on a vehicle, ensuring that repairs meet specific standards of quality and safety. These measurements go beyond simple visual inspection, delving into the technical aspects of car damage repair. By employing precise methods and tools, an auto collision center or vehicle body shop can accurately determine the extent of damage and the effectiveness of the repair process.

This involves assessing factors such as panel alignment, paint quality, and structural integrity. Using advanced techniques like laser measurement and digital imaging, repair quality measurements help professionals ensure that each component of a vehicle body shop’s work is up to par. Ultimately, these measurements contribute to customer satisfaction by guaranteeing that their vehicles are restored to pre-accident condition or even beyond, ensuring safety and reliability on the road.

Why Repair Quality Measurements are Crucial in Auto Restoration

In the meticulous art of auto restoration, every detail matters, and this is where repair quality measurements play a pivotal role. These measurements are not just numbers on a scale; they are the guardians of precision and excellence in car body repair and restoration processes. With an industry that demands the highest standards, especially when dealing with intricate car body restoration tasks, having reliable metrics ensures that every repair is carried out with consistent quality.

Reputable collision repair shops understand that precise measurements are key to customer satisfaction and long-lasting vehicle performance. By adopting advanced measurement techniques, these shops can accurately assess and rectify damage, ensuring the restored vehicle not only looks as good as new but also functions optimally. This, in turn, fosters trust between the shop and its clients, solidifying their reputation in a highly competitive market.

Implementing and Evaluating Repair Quality Measurements: Best Practices

Implementing and evaluating repair quality measurements is a critical step for any auto restoration business, aiming to maintain high standards across their auto body services. To start, establish clear and detailed criteria for what constitutes excellent repair work. This includes not just aesthetic perfection but also structural integrity, ensuring each vehicle leaves the collision center without residual issues. Define key performance indicators (KPIs) such as precision in panel alignment, paint job quality, and corrosion prevention measures to provide a comprehensive framework for evaluation.

Regular training sessions for staff involved in automotive collision repair are essential. Educate them on the latest industry standards and best practices for carrying out repairs. Standardizing procedures ensures consistency in their work, facilitating accurate measurements and identifying areas needing improvement. Encourage open communication among employees to share insights and challenges encountered during auto restoration projects, fostering a culture of continuous learning within the auto collision center.

In conclusion, implementing robust repair quality measurements is paramount for auto restoration professionals. These metrics ensure consistent, high-quality repairs, fostering customer satisfaction and building trust. By adopting best practices outlined in this article, restorers can navigate the process with precision, resulting in impeccable vehicle restoration outcomes.