Repair quality measurements are essential for auto body shops to meet OEM standards, ensuring structural integrity, accuracy, and aesthetic appeal in every repair, from visual inspections to quantitative techniques, ultimately delivering reliable, high-quality repairs that exceed industry benchmarks.

In today’s competitive market, ensuring repair quality is paramount for Original Equipment Manufacturers (OEMs) to maintain customer satisfaction and brand reputation. Repair Quality Measurements (RQM) play a pivotal role in this process by providing standardized criteria to evaluate repair effectiveness. This article delves into the significance of RQM, exploring how they align with OEM specifications to uphold performance standards. By understanding these measurements, businesses can optimize their repair processes, resulting in enhanced product reliability and customer trust.

- Understanding Repair Quality Measurements

- The Role of OEM Specifications in Repairs

- Aligning Measurements with OEM Standards

Understanding Repair Quality Measurements

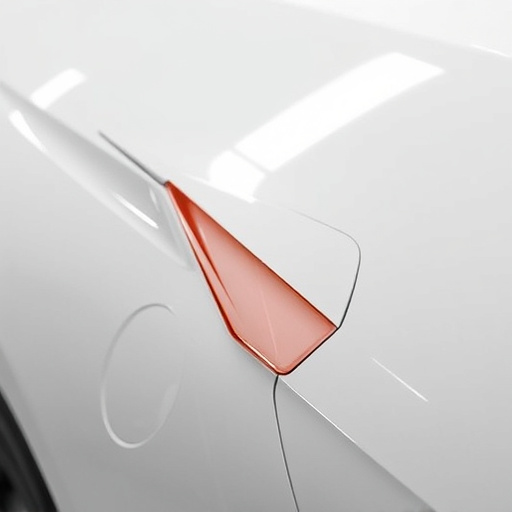

Repair quality measurements are essential tools for ensuring that automotive repairs, including those performed in auto body shops, meet Original Equipment Manufacturer (OEM) specifications. These measurements go beyond simple visual inspections and involve quantitative assessments to verify the accuracy and precision of repair work. By employing advanced techniques and standards, repair facilities can objectively evaluate every aspect of a car body’s restoration, from structural integrity to paint quality.

Understanding repair quality measurements is crucial for maintaining the safety, performance, and aesthetic appeal of vehicles. In an auto body shop setting, these measurements help identify subtle imperfections that might be overlooked by the naked eye. Whether it’s assessing alignment, panel gaps, or paint consistency, each metric contributes to a comprehensive evaluation that guides necessary adjustments. This meticulous approach ensures that the final product not only meets but exceeds OEM standards, providing car owners with reliable and satisfying repairs.

The Role of OEM Specifications in Repairs

OEM (Original Equipment Manufacturer) specifications are the gold standard when it comes to ensuring repair quality. These detailed guidelines provide precise dimensions, material compositions, and finish requirements for every component, from engine parts to auto painting and scratch repairs. By adhering to OEM specs, repair centers can guarantee that vehicles return to their original state or even surpass pre-damage conditions.

Repair quality measurements are instrumental in this process, as they allow technicians to quantify the deviation from OEM standards. Through meticulous inspection and using advanced tools, repairs can be assessed for accuracy and consistency. This ensures that every vehicle repair, whether it’s a simple scratch repair or a complex engine overhaul, meets the rigorous demands of auto manufacturing giants, thus preserving the integrity of both the vehicle and its performance capabilities.

Aligning Measurements with OEM Standards

In the realm of automotive collision repair, aligning repair quality measurements with Original Equipment Manufacturer (OEM) standards is paramount. This meticulous process ensures that vehicle repair services adhere to the stringent specifications set by the car body shop’s creators. By calibrating tools and employing standardized procedures, technicians can confidently achieve results that match OEM parts’ precision and performance.

Such alignment involves rigorous testing and validation against factory-set parameters. Repair quality measurements, thus calibrated, play a pivotal role in upholding the integrity of both individual components and the entire vehicle. This commitment to excellence is what distinguishes top-tier car body shops, ensuring customer satisfaction and vehicular reliability on the road.

Repair quality measurements play a pivotal role in ensuring that vehicle repairs meet Original Equipment Manufacturer (OEM) specifications. By aligning measurement practices with industry standards, repair shops can guarantee the accuracy and reliability of their work. This not only maintains the performance and safety of vehicles but also fosters consumer confidence in the repair process. Embracing rigorous measurement protocols is a key strategy for achieving exceptional repair quality, ultimately contributing to a thriving automotive industry.